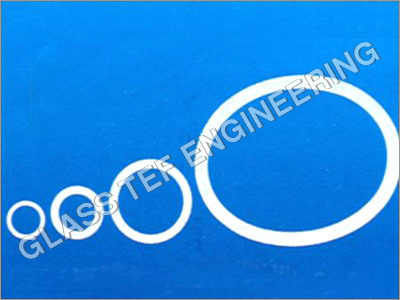

PTFE Envelope Gasket

PTFE Envelope Gasket Specification

- Medium

- Acids, Alkalis, Solvents, Gases, Water and Corrosive Fluids

- Pressure Resistance

- Vacuum to 100 bar

- Gasket Coefficient

- 0.09 to 0.12 (Static)

- Standard

- ASME, ANSI, DIN or as required

- Temperature Resistance

- Up to 260C

- Vaccum Range

- Full Vacuum to atmospheric pressure

- Material

- PTFE (Polytetrafluoroethylene)

- Shape

- Round, Oval, Rectangular or as specified

- Inner Ring

- PTFE or as specified

- Size

- As per requirement (customized sizes available)

- Application

- Chemical, Pharmaceutical, Food, and Petrochemical Industries

- Thickness

- 1mm to 10mm

About PTFE Envelope Gasket

To attain complete customer satisfaction, we have been able to manufacture and export superior quality PTFE Envelope Gasket. This gasket is developed under the strict supervision of our experienced professionals so that the final output meets with the clients' demands. Our offered gasket is manufactured in various dimensions and thicknesses in accordance with the international quality standards. To ensure zero-defect, PTFE Envelope Gasket is thoroughly checked on various parameters by a team of quality controllers.

Other information:

Specification

- Caf Or Non Asbestos Insert With Ss Corrugated Ring

- Tailor Made Sizes Available For Glass Lined Reactor Or Any Application

- Elliptical Manway Sizes 350 X 450 , 300x 400 Available

Exceptional Chemical and Thermal Resistance

PTFE Envelope Gaskets offer unbeatable resistance to chemicals, solvents, and extreme temperatures, making them ideal for applications where aggressive or corrosive media are present. The ability to withstand up to 260C and pressure conditions up to 100 bar ensures safe and long-term operation in demanding industries such as food processing and pharmaceuticals.

Customized Seal Solutions for Any Industry

Manufactured in a range of shapes and sizes, these gaskets are tailored to the unique needs of each client. Whether your system requires round, oval, or rectangular seals, our products are available to match precise application specifications. Compliance with international standards like ASME, ANSI, and DIN guarantees universal compatibility.

FAQs of PTFE Envelope Gasket:

Q: How are PTFE Envelope Gaskets typically used in industrial applications?

A: PTFE Envelope Gaskets are primarily used to create secure seals in piping, flanged joints, and equipment that handle corrosive or sensitive media. Their chemical resistance makes them ideal for processes involving aggressive acids, alkalis, solvents, and various gases, commonly found in chemical, pharmaceutical, and food industries.Q: What are the benefits of using PTFE Envelope Gaskets over traditional gaskets?

A: PTFE Envelope Gaskets provide superior chemical resistance, non-stick properties, and a wide temperature and pressure range. This translates to longer service life, reduced maintenance, and minimal risk of contamination, which is especially crucial in pharmaceutical and food processing settings.Q: When should PTFE Envelope Gaskets be selected for a sealing application?

A: PTFE Envelope Gaskets should be chosen when dealing with highly corrosive fluids, elevated temperatures up to 260C, high-pressure environments up to 100 bar, or when compliance with stringent hygiene or safety standards is required. Customized sizing also allows for precise integration into specialized systems.Q: Where can PTFE Envelope Gaskets be sourced in India?

A: As an exporter, manufacturer, supplier, and service provider based in India, we offer PTFE Envelope Gaskets customized to specific client requirements and supply them nationally and internationally for a wide range of industrial applications.Q: What customization options are available for PTFE Envelope Gaskets?

A: Customers can specify the gaskets shaperound, oval, rectangularor request unique geometries. Thickness can range from 1mm to 10mm, and the inner ring material and size are tailored as needed. International standards, such as ASME, ANSI, and DIN, are followed, or customized standards can be accommodated.Q: How does the manufacturing process ensure gasket performance in critical applications?

A: Gasket production involves selecting premium PTFE material, custom shaping, and rigorous testing for pressure, temperature, and chemical compatibility. Each gasket is made to deliver optimum sealing effectiveness and safety as per international standards.Q: What industries benefit most from PTFE Envelope Gaskets?

A: Industries that frequently handle corrosive chemicals, such as chemical manufacturing, pharmaceuticals, food processing, and petrochemical plants, benefit most from these gaskets due to their durability, adaptability, and safety features.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese