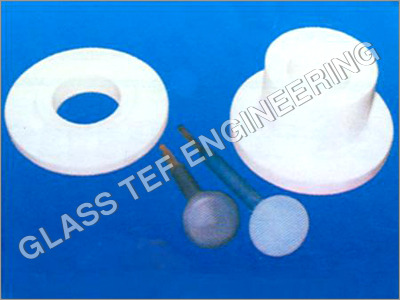

Valve Seat

MOQ : 10 Pieces

Valve Seat Specification

- Product Type

- Valve Seat

- Material

- Mild Steel

- Shape

- Round

- Surface Treatment

- Galvanized

- Section Shape

- Round

- Color

- White

- Warranty

- 1 Year

Valve Seat Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 7 Days

About Valve Seat

Valve SeatBeing a quality-focused organization, we are delivering superior quality Valve Seat. Our offered seat is highly appreciated for its number of features like wear & tear resistance, excellent engine efficiency, tough-built, long lasting nature and helps to exhaust emission. This seat is widely used in grinding machine, internal combustion gasoline and diesel engine applications. As per the needs of clients, this seat is made available in various sizes and specifications. To ensure zero-defect, this Valve Seat is stringently checked on various set industrial parameters.

Product Specification:

- Maintain engine compression ratio

- Engine efficiency

- Helps to exhaust emission

- Augment engine life

- Wear resistance

- Compression gas sealing

Product Features:

- Offers Superior Thermal Conductivity

- Excellent Machining Characteristics

- High Thermal Expansion

- Lowest Wear - Improved Reliability/Durability

- Superior Surface Finishes

- Suitable for HD Intake and Exhaust Seats, Gas and Diesel

- Compatible with Most Valve Materials

Applications:

- Valve seats and seat inserts - seats for all types of valves including ball valves, butterfly valves, gate valves, chokes and plug valves.

- Valve stem seals, including chevron packing and all types of energized seals.

- Complete valves, valve liners and linings

Superior Quality and Corrosion Protection

Our valve seats are manufactured from top-grade mild steel and feature a galvanized finish, ensuring high durability and resistance to corrosion. The white color provides a clean appearance, suitable for diverse industrial environments. This combination results in a product that stands up to demanding conditions, prolonging service life and reducing maintenance costs.

Wide Industrial Utility and Reliable Performance

Engineered with a round shape and section, our valve seats offer excellent functionality across multiple applications. They are ideal for use in piping systems where secure sealing and reliability are critical. Their adaptable design and sturdy construction make them a preferred choice for manufacturers, service providers, and suppliers throughout India.

FAQs of Valve Seat:

Q: How is the white round valve seat installed in piping systems?

A: The valve seat is installed by fitting it securely into the designated section of the piping system. Its round shape and section provide a reliable fit, and standard installation procedures for mild steel and galvanized components should be followed to ensure proper sealing and functionality.Q: What benefits does the galvanized surface treatment offer?

A: The galvanized surface treatment protects the mild steel valve seat against corrosion, rust, and environmental wear. This not only extends the life of the valve seat but also reduces the frequency of replacements and lowers long-term maintenance costs.Q: When should these valve seats be used?

A: These valve seats are suitable whenever durable sealing solutions are neededparticularly in environments exposed to moisture or corrosive substances. They are ideal for a range of industries, including mechanical, industrial, and commercial sectors requiring reliable performance under varying conditions.Q: Where are you able to supply and export these valve seats?

A: We supply and export our white round valve seats throughout India and can deliver to various locations as needed. As a manufacturer, exporter, service provider, and supplier, our distribution network is well-equipped to cater to regional and international demands.Q: What is the process involved in manufacturing your valve seats?

A: Our valve seats are produced using high-grade mild steel. The manufacturing process includes precise forming of the round shape, followed by a galvanized surface treatment and a stringent quality check to ensure each seat meets our durability and performance standards.Q: How can users benefit from your one-year warranty?

A: Every valve seat comes with a one-year warranty covering manufacturing defects. Should any issues arise within this period, customers can contact us for repair, replacement, or support, ensuring peace of mind and added value with every purchase.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese